Phone : 215.766.3066

Complex CNC Milling - Aluminum, Steel, Misc. Materials

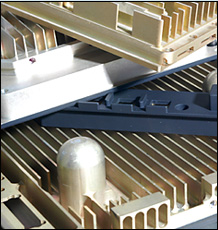

We Specialize in complex CNC Milling. Our 5-axis equipment has the capability of handling a small to medium size parts (our largest table is 60" x 40") and hold tolerances up to /-.0001. We can handle small volume prototypes as well as medium to large volume production. We have extensive expertise in aluminum hog-outs for the aerospace industry, as well as machining steel, plastics, and many different miscellaneous materials. Facilities List - Click HerePrototypes & Machine Building

Our personnel have exceptional skill and experience in producing prototypes, fixtures, tooling, and specialized machinery to fit specific manufacturing needs.Quality Control

Our highly skilled and experienced inspectors utilize the latest in technology to help our company to consistently exceed the high quality expectations of our customers. We utilize 2 CMM's and a multitude of highly precise instruments traceable to NIST to monitor our production in the most efficient and precise manner. We perform in-process inspections on all parts manufactured and have the capability of providing our customers with first article inspection reports in accordance with specified requirements.Programming

Our programmers have years of experience as machinists and programmers in the avionics and aerospace industry. The methods used are unique and are continually refined to allow for maximum utilization of our machining centers while maintaining consistent quality. This expertise has given us the reputation of being the "go-to" shop for the highly complex and critical parts.Finishing Processes

We have carefully selected only the highest performing suppliers to perform our plating and painting processes. Our finishing department maintains tight control over the processes our suppliers perform and maintains documentation of performance and certifications of the services provided.Call us at 215.766.3066 or fill out the form below for quick response